What Is Melamine: A Brief About Melamine And Its Uses

The demand for Melamine in recent years has risen due to many power-rendering factors—heat resistance, glossy structure, durability, and moisture resistance, to name a few. The end-use businesses like automotive, manufacturing, textile, food and beverage, and many others drive market growth with the effective use of Melamine and resins.

Melamine resins have seen an amazing increase in demand with wood adhesive production, bonding applications in hardwood, and fibreboard with laminates. Additionally, the increased use of Melamine foams and resins serves the industries that use thermoset plastics, concrete, and carbon nanotubes. In this blog, let’s discuss the characteristic features of Melamine, Melamine uses, and their industrial applications in detail.

What is Melamine?

If you wonder, what is Melamine all about, let’s define it in a shot— a top-quality resin chemical compound, both nitrogen-rich and highly organic.

There are various ways to manufacture Melamine: either Urea, Hydrogen Cyanide, or Dicyandiamide. Urea is the primary material that industries go for to commercialize Melamine production currently. In this process, Urea breaks down to form Cyanuric acid, which further undergoes a chemical reaction to give Melamine.

Melamine uses have also contributed to an improved application in the production of plastic products, plates, bowls, paper-based products, industrial coatings, etc. Due to its outstanding properties and being highly organic, it is also used as fertilizer in some places.

The Melamine resins are fire/heat resistant and unbreakable to a great extent which makes their products most desirable compared to the other plastic alternatives.

Also Read: What are the Different Types of Resins?

The Chemistry of Melamine

Being a heterocyclic organic chemical compound, Melamine acts as a chemical intermediate, solvent stabilizer, and good solvent.

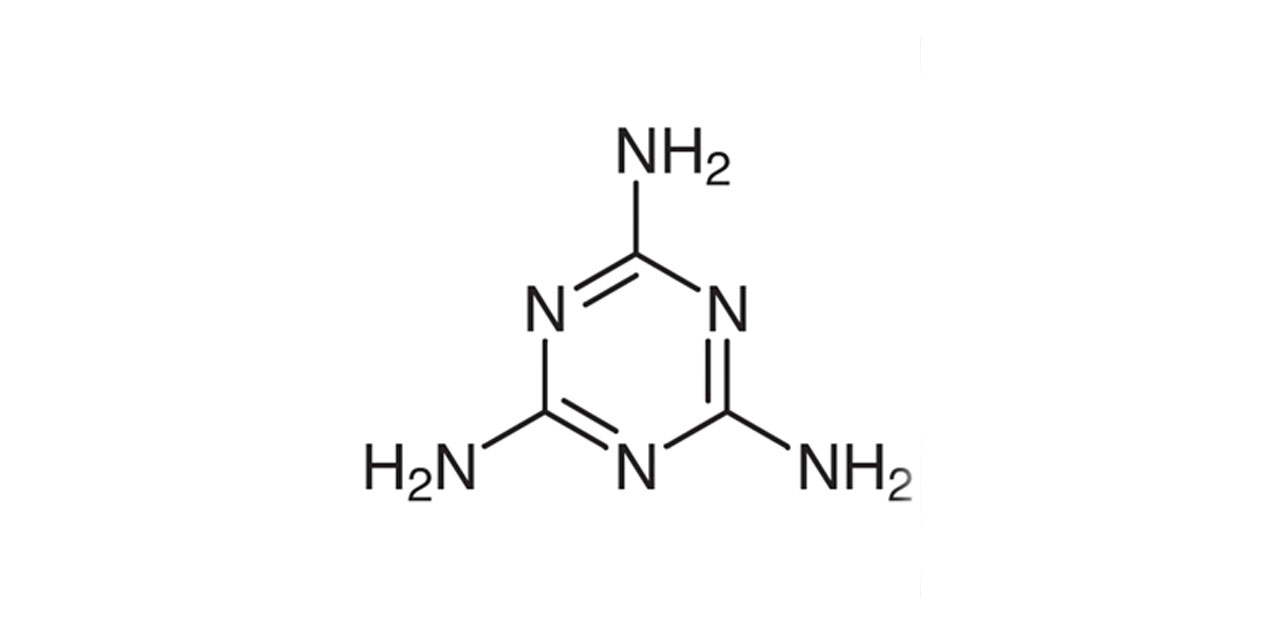

The chemical formula of Melamine is C3H6N6 and other chemical names are Cyanuramide or Triamino Triazine. One Melamine molecule consists of three Carbon atoms, six Hydrogen atoms, and six Nitrogen atoms.

Also Read: What Are The Best Paint Raw Materials

Properties that make Melamine a top industrial pick

The market size for Melamine is expected to hit 2.6 billion USD by 2026, with an improved CAGR of 4.2% as compared to 2021.

Melamine uses have fixed the roots in the market due to the following exceptional properties the compound exhibits compared to the others.

- Present in crystalline form

- Exists as a colourlesscompound

- Part of the heterocyclic organic compound family

- Nitrogen-rich organic compound

- Since it encourages nitrogen content release after burning, it is highly flame retardant

- Combines with formaldehyde to produce thermosetting plastic

- Has harmful consequences to the human body

Also Read: What is Monobasic Acid: All You Need To Know

Core characteristics of Melamine contributing to Industrial applications

Melamine has many properties that make it desirable for a plethora of applications. Melamine resin is a highly durable and hard thermosetting aminoplast that portrays high heat resistance and fire resistance. Melamine resin co-reacts with Urea-Formaldehyde to avoid the degradation of adhesive bonds. The particle boards that use Melamine-Urea-Formaldehyde contribute an appreciable resistance to chemicals, scratch, heat, and moisture than any other wooden boards.

Insulating property

The Melamine form as discussed earlier is a good component in building insulations that have difficult pore structures. The foam is the best to insulate both ducts and pipes. Melamine Foam is also a wonderful addition to auditoriums, stages, and studios to encourage soundproofing techniques.

Due to the release of Nitrogen, while burning, Melamine foam is an amazing cleaning abrasive. It can replace sandpaper to clean the pores and small grooves. The markers, crayons, or even greasy surfaces can turn clean with the effects of Melamine foam.

Flame resistance

Melamine resin is used prominently in plasticware— it can keep the heat from melting or warping plastics to ensure the durability is high. It also finds applications in the floors and walls to make them less inflammable so that they control fires before they build flames.

It acts as protective clothing like thermal liners, firemen uniforms, aprons, and gloves due to its fire-proofing properties. Manufacturers use these versatile and flexible materials to fit the textiles based on the texture, color, fiber, width, and other customer preferences.

Low Density

Compared to natural wood, particle boards offer high-end fabrication. They are more cost-effective than ordinary plywood or any other fiber boards of medium density. Since particle boards are easier to take along and lighter, the handling labor charge is much easier.

The particle boards have a great surface, hence a bit of staining and lacquering can help them maintain a pleasant look which is difficult to achieve using plywood. Melamine can help build industrial grade, commercial grade, countertop grade, and shop grade particle boards.

Increase protein content

Melamine is a regular ingredient in desserts, liquid milk, cereal products, yogurts, milk products, powdered infant formula, biscuits, frozen food, and protein powders. FDA encourages Optimal levels of Melamine in food for consumption purposes.

The ideal level of Melamine can help elevate the protein level in the food. However, the consumption of Melamine in large amounts with co-ingestion of Cyanuric acid has been reported in the urinary stones in infants.

Ultra-plasticizing

Melamine resins act as good concrete enhancers. When you add Sulphonated Melamine formaldehyde to concrete, it produces a plasticizer that can impart high resistance to the concrete. This additive helps to minimize the water content in concrete and maintains fluidity till it is poured for the final shape.

As a result, you get concrete with the least porosity and the best mechanical strength. It exhibits durability while managing weather/environmental fluctuation, to avoid erosion and result in a longer lifespan.

Resin Lamination

Melamine resin is a great addition to laminating applications due to its superior heat resistance, scratch resistance, and hardness. It doesn’t color irrespective of what you apply to it, so you can independently apply it to every surface of your choice.

Though they are expensive compared to P-F resin laminates, Melamine laminates are largely popular for decoration applications. They have protective features and are widely used for tabletops to protect the table, keeping it away from scratches and stains.

Also Read: Castor Oil Price In India: All you Need To Know

Melamine Uses at a glance

The combination of Melamine with Formaldehyde gives rise to Melamine resin. Under high heat and pressure, Melamine disperses water that can make plastic unstable unless removed. You obtain Melamine resin after the complete polymerization process.

They are heat-tolerant and fire-resistant molding compounds with great stability in structure. They are widely used in whiteboards, kitchenware, floor tiles, commercial filters, and fire-retarding fabrics. While warm, you can easily mold them to a fixed pattern that makes them ideal for industrial applications.

It is called thermoset plastic since you can fix the plastic once the molding process completes. If you expose Melamine to high heat, it melts. So Melamine dishware can’t withstand high temperatures, like microwaves or ovens.

You can also use Melamine to give birth to foam products– a unique structure with stacked bubble shapes, very hard, and cleans various substances. These are ideal to remove dirt and scuffs from different surfaces.

Melamine resins are used in construction products, which are essential to coat fibers in the top layer of the construction material. They make the end product heat resistant to let hot objects settle on the counter without any hassle.

The presence of Melamine has also proved to be useful in manufacturing certain filters. This compound being porous will let substances go through it, however, you can use it to filter out certain particles of specific size. The Melamine filters can manage huge capacity that you can use in humid environments due to heat-resisting characteristics.

Melamine-based Resins and Uses

There are various types of Melamine resins in the market used for everything that range from laminate decors, wood products, flooring, countertops, coatings and paints, dinnerware, textile, paper, and many more. Melamine Resin Suppliers in Delhi distribute these wide ranges of resins to the industries for their manufacturing purposes and the development of unique products. The types of these resins include:

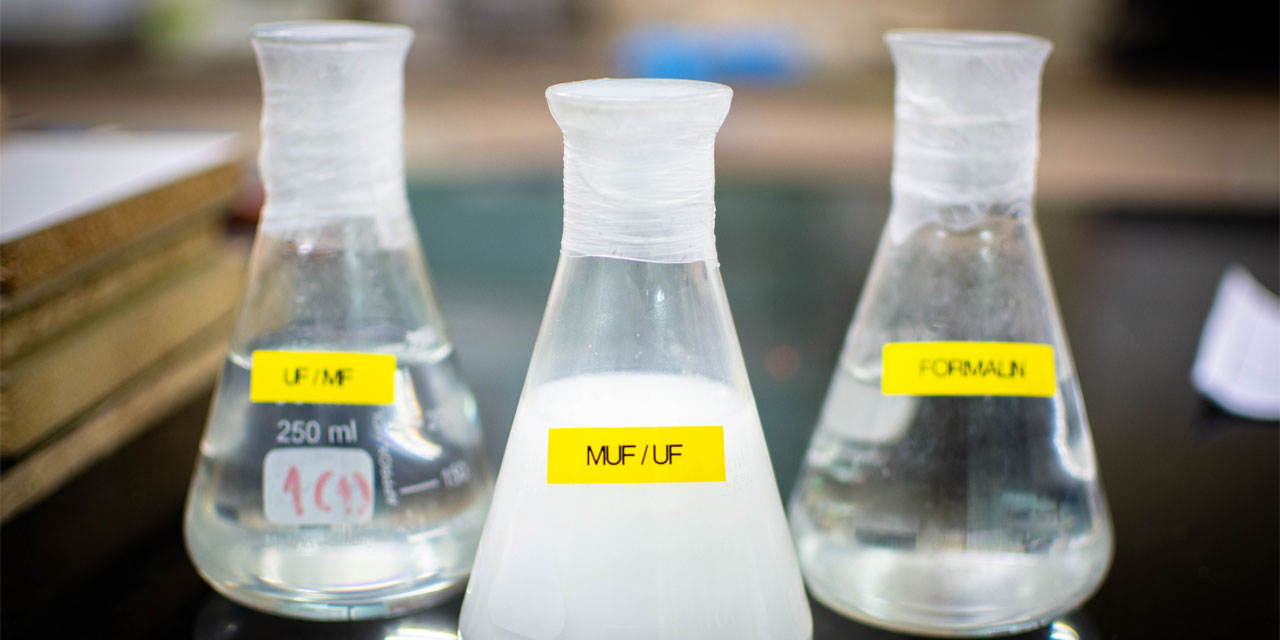

- Melamine Formaldehyde resins are used mainly for laminates and decor purposes;

- Melamine Urea Formaldehyde resins are used to produce water-resistant OSBs ( Oriented Strand Boards), fibreboard, or particleboard;

- Methylated Melamine Formaldehyde resins are utilized in textiles, paper, coatings, etc, in the form of modifiers;

- Melamine Urea Phenol-Formaldehyde Resins for particle boards.

Melamine Formaldehyde (MF) Resins

MF resins are highly durable yet hard thermosets that possess heat and fire resistance to a great extent. They are also long-lasting and solvent-resistant resins with specific applications as follows:

- Cabinetry

- Laminate flooring and countertops

- Composites

- Textile finishes

- Surface Coatings

- Paper binding and paper processing

- Tires, fertilizers, textiles, metals, and glass Modifiers

Melamine Urea Formaldehyde (MUF) Resins

MUF resins are significantly used in fibreboard and OSB manufacturing purposes due to their high-end durability and water-resistant features.

Methylated Melamine Formaldehyde Resins

When Melamine resins undergo the addition of excess methanol during manufacturing, they form Methylated Melamine Formaldehyde Resins. When the structure of MF polymer incorporates the Methoxymethyl group, it produces high-end stability.

These resins exhibit good stain and scratch resistance in catalyzed systems and wooden coatings. Also, it can develop fabric stiffness through the cross-linkage of latex emulsions to cater to textile applications.

It is stable to use effectively in water-based products, and highly suitable for various applications like cross-linking, industrial coatings, non-wovens, textiles, papermaking, etc.

Melamine Urea Phenol-Formaldehyde (MUPF) resins

Melamine Urea Phenol-Formaldehyde (MUPF) resins can suit the manufacturing process of OSBs, ie. Oriented Strand Boards.

Also Read: What is Linoleic Acid: All You Need To Know

Wrap Up

While Melamine is a boon to various industrial applications, it can turn hazardous unless carefully stored. Also, remember, Melamine consumption can be harmful if the Melamine level exceeds the limit for its safe use.

Looking for a trustworthy distributor of Industrial Resins and chemicals? Bansal Trading Company is one of the most trusted Melamine Resin Suppliers in Delhi that deals with timely distribution of Melamine resins to help you with the various industrial needs.

With 60+ years of catering to multiple industries with chemicals, raw materials, and resins, BTC has established a trademark in serving clients with the best.

BTC_WEB_ADMIN